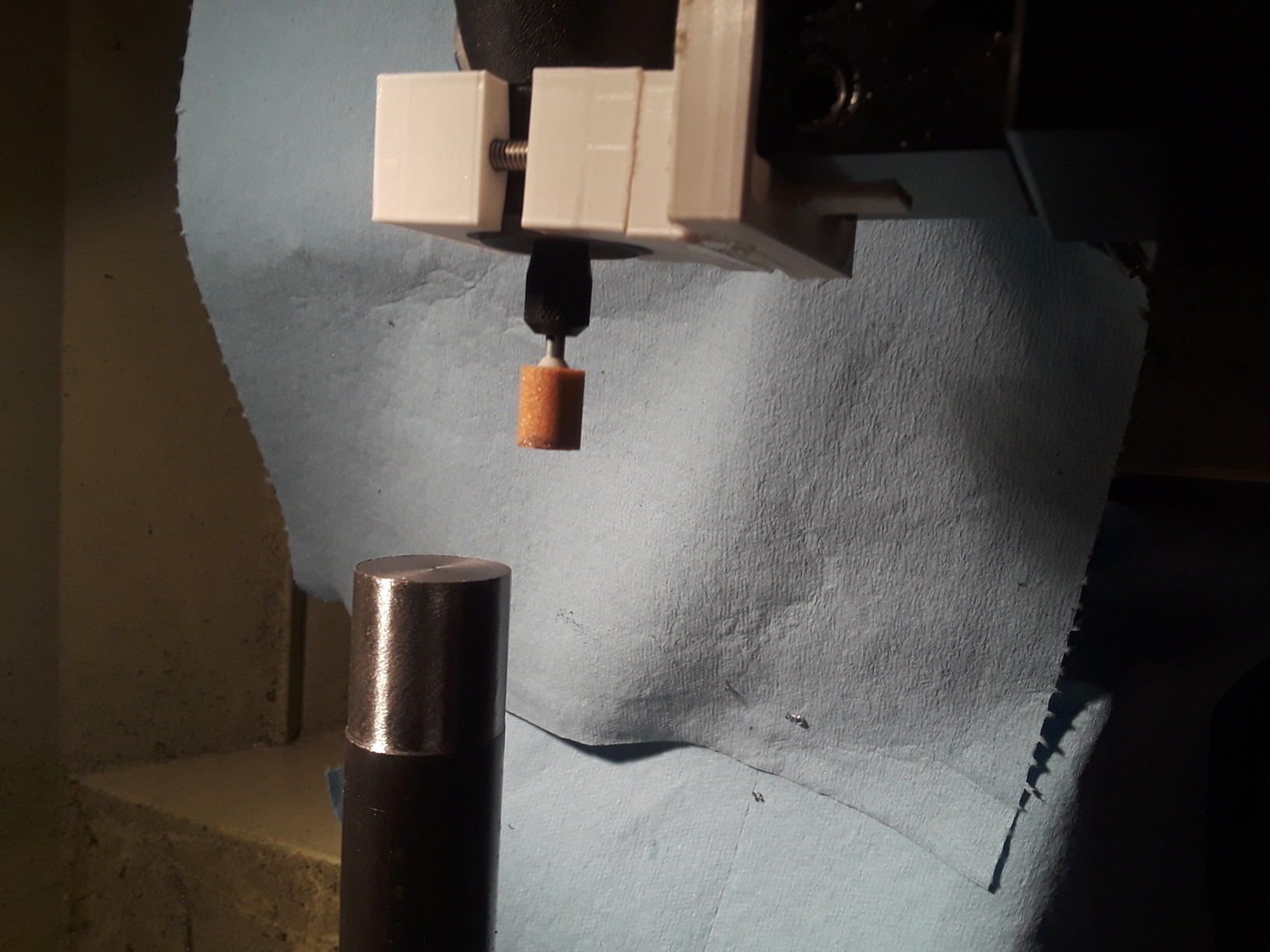

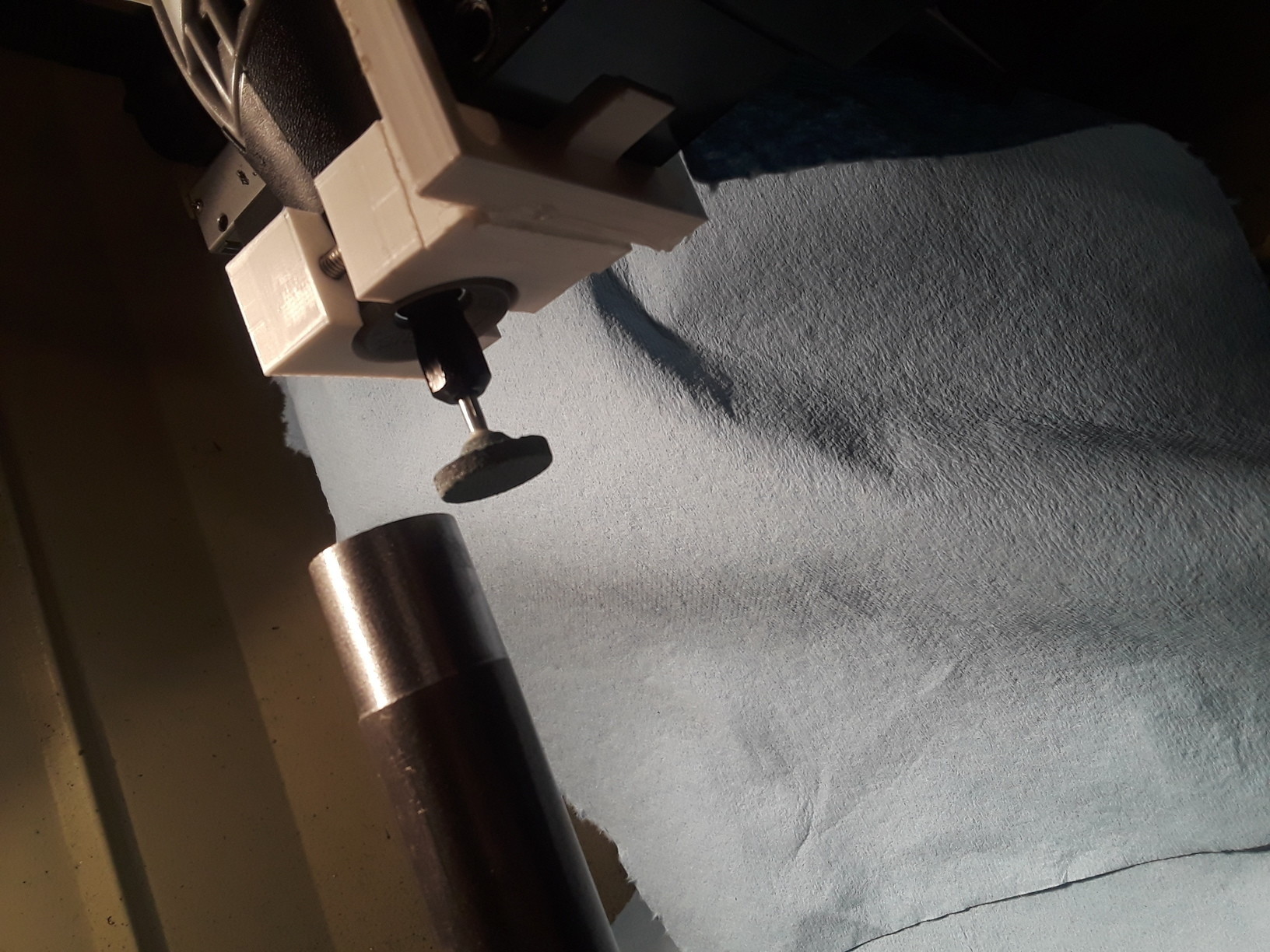

I’ve worked out a quick and dirty holder for a dremel for my lathe toolpost. I made it out of 3d printed plastic, because the entire dremel is plastic. There is nothing to reference really on this curvy molded thing, no mounting posts to grab hold of (just one possible screw thread up front.) I made the holder to clamp it to a 0.5″ shank in two places with this inverted toroidal frustrum clamp thingy.

There isn’t a lot of tool-force on a grinding wheel, so my hope is that this plastic monstrosity will allow me to do precision grinding on my lathe. How precision? Well, with the standard (perhaps too coarse-grained) grindy-wheels that come with the dremel, I’m getting better surface finishes than with my random carbide cutter.

The grit is going to be a problem. I must keep it out of the rest of the machine at all costs. Best thing I’ve come up with so far is a flexible shop-towel barrier weighed down at the ends.

Pro-tip: When working with 3d printed plastic, you can stick PLA parts together very easily and very strongly with superglue and tower-hobby CA accelerator. The bond is almost as strong as the plastic itself. This allows you to do all sorts of lego-like things with parts you have to print out as multiple prints, due to the limitations of how the printing process works.

Also: Here is the download for the scad and stl files for putting the holder together. You may need to print different spacers cubes, depending on how things work out. Stick it all together with superglue.

Recent Comments: