Last week I made a trip to Menards, a local midwestern home improvement store. Menards makes Home Depot and Lowes look pathetic. The quality of their wood is also amazing. Actually, I made two trips to Menards. 😛 The first one, then a bunch of woodworking mistakes, then a second trip for more raw materials.

There is a spot in my office that is bare right now that could use a 27″x60″ table jammed in the corner.

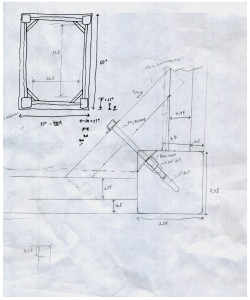

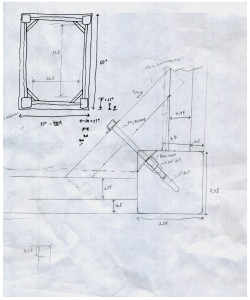

I made some plans.

I assembled a tabletop (after learning a trick to plane the wood.) Glue joint down the middle. Edges planed together in a vise so that they’ll fit together almost perfectly. The thing was flat enough that I didn’t have to flail around on it with the woodplane.

I then cut those beautiful pine boards (seriously, they’re square, and sanded almost polished until they slide against one another.), measured and glued them down to the tabletop. This makes the frame which hold the legs.

I ordered four “foursquare” 2.25″x29″ legs from tablelegs.com

I then drilled and glued down the corners – the hardware pulls the legs against the frame producing a satisfyingly rigid, yet detachable joint.

I created some V-blocks so I could squarely (more or less!) drill into the corners of each table leg. I inserted a threaded 1/4″-20 brass insert into the wood (courtesy of the local hardware store).

The table was finally assembled today. Then I quickly stained it and will leave it to dry over the next two weeks.

There are a few small errors in the project which would probably make this unsellable. It is, however, pretty good for a first try, almost professional, and functional. When it finally dries, I’ll furniture polish it and place it in my office – more flat space to clutter up with junk! I mean, to work on.

There are a few small errors in the project which would probably make this unsellable. It is, however, pretty good for a first try, almost professional, and functional. When it finally dries, I’ll furniture polish it and place it in my office – more flat space to clutter up with junk! I mean, to work on.

Recent Comments: